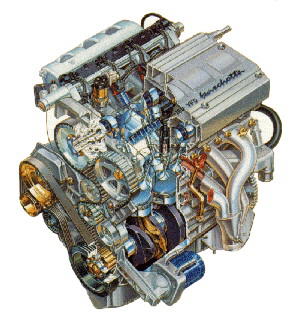

The Hitachi control-unit will operate the hydraulic camshaft-adjuster.

It can either be off (when idle or for increased power) or on (increased torque), but only when the

cooling-fluid temperature is higher than 40°C / 104°F.

When on, it will bring the valve-timing forward by 25 crankshaft-degrees.

Depending on the engine-load (calculated by parameters of the air-quantum-meter

and the rev-count-sensor), the system will be turned on at 1700rpm (high load; TP=2¾ ms) to

2400rpm (low load; TP=1½ ms), and will be shut off again at 4700rpm.

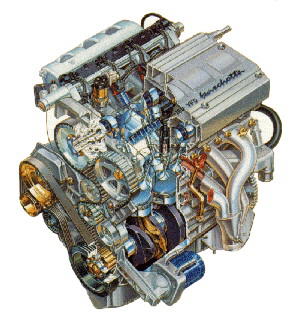

An electro-magnet will shift a valve-set with oil-channels. Oil will reach

an oil-chamber where it will push a plunger axial towards the engine.

Because the plunger is slanted cogged at the outside, it will produce a

clockwise rotation. Through a cog this will turn the camshaft.

When the NGK pink-sensor registrates pinking, the ignition-time will be

quickly delayed in 2° steps until a maximum of 6°. I will then

be slowly restored unless pinking occures again. The Hitachi control-unit

will memorize the delay-time and situation for later occurences.

When the pink-sensor fails, the system will default to bringing forward the

ignition-timing with 5° when the engineload is more than 2½ ms.

When one of the many sensors fail, the Hitachi control-unit will start a software recovery-program to keep the engine running as shown in the pink-sensor example above.